Hi-Tensile Verlok® Vertical Mineshaft/Borehole Cable provides a unique and superior alternative to all other vertical riser cables, including steel wire armour (SWA).

Hi-Tensile Verlok® cables feature a totally encapsulating patented design with built-in, high-tensile strength pulling members. With this revolutionary integrated design, the built-in high-tensile pulling members take the mechanical strain – not the electrical conductors. That means greater safety and longer cable life.

The completely locked-in unified construction of the Hi-Tensile Verlok® Vertical Mineshaft/Borehole Cable also results in virtually no internal component slippage.

Hi-Tensile Verlok® Vertical Mineshaft/Borehole Cable eliminates other critical problems associated with short to long vertical self-support installations such as birdcaging of wires, poor hoop strength, conductor elongation and insulation cracking. Moreover, the Hi-Tensile Verlok® core-encapsulating ribbed inner jacket, embedded steel interlocked armor, and uniquely extruded outer jacket provide the ultimate in mechanical cable protection, stability and flexibility. Hi-Tensile Verlok® can use standard interlocked armor cable connectors; simplifying armor connection.

Hi-Tensile Verlok® Vertical Mineshaft/Borehole Cable provides power, control, and communication transmission capability in ratings up to 46,000V and in vertical self-support lengths beyond 2000 feet (600m).

For each application, the cable is custom-designed to meet your specific needs. It is manufactured according to the highest quality standards. Since its inception, Hi-Tensile Verlok® has been successfully utilized by progressive companies throughout Canada and the United States and is rapidly becoming the new standard.

- Longer allowable vertical and horizontal pulls

- Easier to install due to torque balanced design

- Eliminates cable inner core slippage

- Standard interlocked armour cable connectors

- Greater hoop and impact strength

- Designed to industry safety standards

- No armour birdcaging

- Standard interlocked armour cable connectors simplify armour connections

- Encapsulated cable core minimizes any possible fluid migration

- MSHA and CSA approved (HL/FT4)

- Meets the Safety Factor requirements of ICEA mining standards

- Encapsulated internal core prevents slippage during installation and in service, particularly during system electrical faults

- Prevents long term creepage of internal core

- Pulling is primarily done by flexible high-strength steel members, thereby eliminating conductor elongation and resulting hot spots, cable failure and potential fire

- Resists sharp object penetration into cable core

- Flame retardant (FT4)

- Suitable for hazardous locations (HL)

- Lower installed cost

- Minimizes shaft downtime

- Each installation is designed to meet industry safety standards

- Available in voltages up to 46 kV and lengths up to and beyond 2000 feet

- Longer vertical and horizontal pulls are possible

- Smaller bending radius than SWA resulting in lower cost, fewer splices and improved system reliability

- Pulling is primarily done by flexible high strength steel members

- Higher resistance to mechanical impact (flyrock, etc.)

- Uses standard interlocked armour cable connectors

- Available in XLPE or EPR Insulation, and also in Instrumentation, Communication and Composite constructions plus colored outer jackets

- Factory preparation for pulling eyes available as an option

- Designs available for Single point suspension (boreholes, etc.)

- Optional low-smoke, low toxicity outer jacket available

- MSHA and CSA approved (HL/FT4)

The Hi-Tensile Verlok® mounting bracket saves a significant amount of time and cost in the installation of the cable. Each bracket is custom designed with your mine in mind (specific wall condition, other cables and pipes already installed). The standard bracket is made of standard steel which would be cleaned and painted by the installer while painted and galvanized brackets are available. Stainless steel brackets can be produced and highly recommend in corrosive environments.

- Reduces the cost of installation

- Simplifies installation

- Exact cable O.D. not required

- Pre-install for increased efficiency

- Faster bracket and cable installation minimizes shaft downtime

- Additional posts available for more cables, etc.

- Increased cable surface grip for superior hold

- Utilizes standard band-type clamps; no need for customized clamps

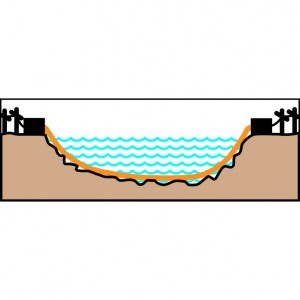

Hi-Tensile Verlok® is the ideal design of vertical and horizontal electrical power and control cable for not only underground mining applications, but also for open pit mines, high-rise buildings, submarine crossings and industrial utility facilities where tensile strength is essential.